Bizen, Okayama

A rich production area surrounded by bountiful mountains

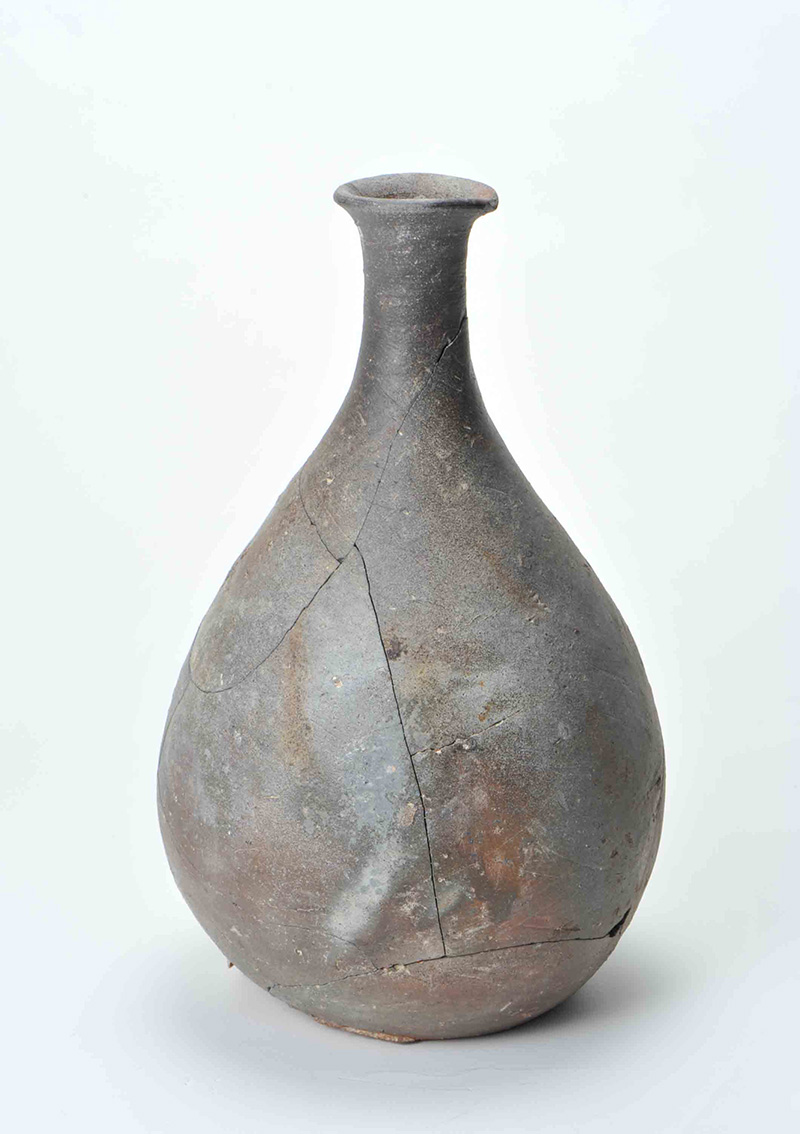

Located in the southeastern part of Okayama and facing the Seto Inland Sea, Bizen’s climate is mild and moderate. The area is known for its great access, being located at the intersection of one of the three major rivers in Okayama, the Yoshii River, and the Sanyo Road, which runs from Yamaguchi to the Kinai area (areas close to Kyoto). Bizen ware first began with the creation of bowls, plates, and tiles in Kumayama at the end of the Heian period(Heian period:794-1185). In addition, the western part of Bizen, the Inbe area, is surrounded by the Furo, Io, and Kayaharayama mountains, which are made up of rhyolite volcanic rock and contain a rich variety of soil called “hiyose”. Hiyose was widely used in Bizen ware, which is one of the reasons behind pottery production in the area.

Early Bizen ware was fired in the peaks of the Kumayama Mountains, but as the popularity of Bizen ware grew and the kilns grew larger, the kilns were moved down into the villages for convenience and for transportation purposes. During the Azuchi-Momoyama period(1573-1603), it is believed that the potters who trained in Bizen began to guide pottery making in Kaga, Toyooka, Tamba Sasayama, Maizuru, and Yanai, as products imitating the form of Bizen ware appeared on the market. From this, it is evident that Bizen ware had established itself as a distinct aesthetic brand. In the Edo era(1603-1867), Mitsumasa Ikeda, the feudal lord of Okayama, made intensive efforts to develop Bizen ware. He offered fuel and materials to potters and designated skilled potters as "Master Craftsmen". It is said that the first multi-chambered climbing kiln was opened in 1831 in Bizen, and, with repeated renovations, the kiln continued to be used until around 1940/1941.

Visit Constituent cultural properties

The remnants of kilns under excavation

The remnants of kilns under excavation